The disposal of Municipal Solid Waste (MSW) continues to pose a significant environmental challenge in urban areas worldwide. In India, nearly 80-90% of MSW is landfilled without any proper control measures. When MSW is discarded without pre-treatment, it can lead to significant pollution of air, land, and water. The primary risks of landfilling MSW include leachate formation, which contaminates groundwater, and the generation of harmful greenhouse gases.

Globally, MSW generation amounts to 2.01 billion metric tonnes annually, with projections suggesting it will increase to 3.40 billion tonnes by 2050, averaging 0.74 kg per person per day. In India, MSW generation is not only rising every year but also undergoing a shift in composition. In 2019, the OECD estimated that India generated over 18 million metric tons of plastic waste annually. According to the Annual Report on Solid Waste Management (2020-21) by the Central Pollution Control Board (CPCB), India generated 160,039 metric tons of waste daily, with 95.4% of it being collected. Around 50% of this waste underwent treatment processes, while 18.4% was sent to landfills.

Changes in consumption patterns have led to an increase in the amount of plastic and packaging materials, such as multi-layered plastics, in MSW. A 2015 study by the CPCB in 60 cities estimated that 9.4 million tons of plastic waste were generated in India in 2017-18, with plastic waste accounting for 3.1% to 12.5% of total MSW.

By 2031, urban India is projected to generate 107.01 million tons per year, increasing to 160.96 million tons annually by 2041—nearly five times the current waste production over the next four decades.

Management of solid waste in India

MSW consists of waste from residential, commercial, and institutional sectors, as well as construction and demolition debris and waste from municipal services. It can be further categorized into wet and dry waste. Wet waste, rich in moisture and organic content, is suitable for composting and energy conversion, while dry waste, which includes non-biodegradable and slowly biodegradable materials, is ideal for recycling and reuse.

While there are various methods for managing MSW, including recycling, landfilling, composting, and incineration, each method has varying environmental impacts and challenges. Landfilling, the most commonly practiced in India, results in soil and water contamination due to leachate from decomposing MSW, while incineration can release harmful emissions such as dioxins, furans, particulate matter, and heavy metals like mercury and lead into the atmosphere, posing significant threats to global health and the environment. MSW management faces the challenge of limited land availability for treatment plants and disposal sites. Although recycling and composting offer environmental benefits such as resource conservation, energy savings, and reduced greenhouse gas emissions, their implementation in India is hindered by weak legislation, poor enforcement, and low public compliance.

Currently, much of India’s MSW ends up in legal and illegal landfills or is burned in the open. The accumulation of waste in landfills leads to methane gas (CH4) emissions, a potent greenhouse gas with a global warming potential 34 times greater than carbon dioxide (CO2). Open burning contributes to emissions of carcinogenic substances, further complicating waste management efforts.

The lack of infrastructure for plastic waste management, poorly managed recycling facilities, inefficient waste collection systems, improper disposal practices, and lack of public awareness all contribute to the growing challenge of plastic waste management in India and its threat to the global environment.

Waste-to-Energy – A better option over landfilling and incineration?

Waste-to-Energy (WtE) from MSW is gaining interest in India as it offers valuable energy services, reduces waste volume, and helps mitigate some of the health and safety hazards associated with current waste management practices. Technologies like anaerobic digestion, gasification, pyrolysis, and mechanical biological treatment can convert waste to energy, reduce harmful emissions, and contribute to circular economy goals by repurposing waste materials. Thus Waste-to-energy is often promoted as a cleaner alternative to traditional incineration, however, challenges remain. One major issue is the low calorific value of mixed MSW in India, which is around 1,500 kcal/kg—much lower than coal, which has a calorific value of around 8,000 kcal/kg. Additionally, the high cost of energy production from waste (Rs 7-8 per unit) is significantly higher than the cost of power from coal, hydroelectric, or solar sources (Rs 3-4 per unit). Another challenge is the disposal of ash generated during waste-to-energy processes, which still require landfilling.

Evolution of Refuse Derived Fuel

One of the major challenges in plastic waste management is the widespread use of non-recyclable plastics, contributing approximately 2.5 million tons of waste to landfills each year. This issue is compounded by improper waste handling, insufficient recycling infrastructure, resource conservation gaps, and significant environmental pollution. To tackle these problems, Refuse Derived Fuel (RDF) has emerged as an innovative solution. RDF is produced by processing municipal solid waste (MSW), where non-recyclable materials are segregated, shredded, and treated to create a stable and consistent fuel. It includes combustible waste components such as plastics, paper, textiles, and biomass, offering a sustainable alternative for waste utilization.

Managing MSW as per waste management hierarchy

In waste management, the European Union’s Waste Framework Directive outlines a waste hierarchy, prioritizing waste management methods from most favourable to least favourable. Co-processing falls in the middle—below reuse and recycling but above incineration and disposal. This makes it an ideal solution for non-recyclable waste, such as orphan plastics, which would otherwise end up in landfills or oceans

Co-processing in cement kilns – The best solution

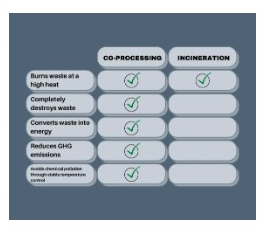

Co-processing in cement kilns is a highly effective, environment-friendly, and sustainable method of waste disposal, particularly when compared to landfilling and incineration. It helps reduce emissions and leaves no residue after treatment. By converting plastic waste into energy, cement kilns reduce the need for coal, a major contributor to global warming, while keeping waste out of landfills and oceans. Plastics, which have both material and energy value, are efficiently utilized in cement production without compromising emissions or product quality.

Cement kilns operate at extremely high temperatures (around 1400–1600°C), ensuring that waste materials are completely combusted, minimizing the release of toxic emissions like dioxins, furans, and heavy metals. Unlike landfills, where waste decomposes inefficiently and incineration, which can produce harmful residues, co-processing leaves no residual waste. Furthermore, co-processing supports a circular economy by transforming waste into a resource. Instead of being discarded in landfills or incinerated, waste is integrated into production processes, reducing the need for virgin materials and energy.

In conclusion, co-processing in cement kilns offers a viable, sustainable alternative to landfilling and incineration, helping to mitigate the environmental impacts of waste while contributing to the circular economy.

In India almost all cement companies are co-processing waste in their cement kilns. RDF is one of the most common fuels which is being utilised. At JSW, we are co-processing RDF at two of our clinker units currently – Nandyal and Shiva. In our Nandyal plant, we have achieved ~10 % of TSR in FY 2023-24 particularly with RDF being the primary alternative fuel. We have co-processed ~58000 T of RDF along with other industrial waste. This has helped us in avoiding ~ 50,000 ton of CO2. For this achievement, JSW Nandyal Team has recently received the Platinum Award for Highest Plastic & RDF Co processing and Silver award for Highest TSR % in 2023-2024 on 14th international conference on “Sustainability Waste Management – Circular Economy & IPLA Global Forum 2024.

RDF co-processing is also helping us to comply with Extended Producer Responsibility (EPR) regulations, which are designed to ensure that producers take responsibility for the entire lifecycle of their products, including waste management.

Conclusion

The use of dry MSW and RDF in cement kilns as an alternate fuel provides a sustainable solution to two pressing urban challenges: waste disposal and reducing the carbon footprint of cement production. This approach offers significant environmental benefits, such as reduced landfill usage, lower CO2 emissions, and improved energy efficiency. Furthermore, RDF utilization promotes a circular economy, contributing to sustainable urban waste management. As cities worldwide continue to search for viable paths toward zero landfill waste, integrating RDF into the cement industry presents a promising, scalable solution that can help meet both environmental and economic goals.

Going forward we should work towards a favourable policy frameworks which can promote RDF co-processing by establishing clear quality standards and guidelines for RDF, offering tax incentives for cement plants adopting co-processing technologies, and supporting infrastructure for RDF collection and sorting. Additionally, integrating RDF co-processing into national waste management and circular economy strategies, offering research funding for R&D, and enforcing strict monitoring and compliance mechanisms are key. Public awareness campaigns and market incentives for RDF-based products can further drive participation and the growth of this sustainable waste management solution.

Arya, R. (14 July 2022). Particle Size Distribution from Municipal Solid Waste Burning over National Capital Territory, India.

Bansal, D. (August,2023). Characterization of MSW incineration bottom ash for use as structural fill in reinforced soil structures: Geoenvironmental, geotechnical and economical assessment.

(Ngwabie et al. (March 2019) Quantifying greenhouse gas emissions from municipal solid waste dumpsites in Cameroon.

Das, B. (September 2018). Estimating emissions from open burning of municipal solid waste in municipalities of Nepal.

Kara, M. (November,2012). Environmental and economic advantages associated with the use of RDF in cement kilns.

Kosajan, V. (April 2021). Municipal solid waste (MSW) co-processing in cement kiln to relieve China’s Msw treatment capacity pressure. Resources, Conservation and Recycling, 105384.

Maalouf, A. (June 25, 2020). Global municipal solid waste infrastructure: Delivery and forecast of uncontrolled disposal. Waste Management & Research: The Journal for a Sustainable Circular Economy.

Ojha, V. (October,2024). Resource recovery from legacy waste dumpsites in India: A path towards sustainable waste management.

Sauve, G. (1 May 2020). The environmental impacts of municipal solid waste landfills in Europe: A life cycle assessment of proper reference cases to support decision making. Journal of Environmental Management, 110216.

Tihin, G. L. (1 December 2023). Overview of municipal solid wastes-derived refuse-derived fuels for cement co-processing. https://www.sciencedirect.com/journal/alexandria-engineering-journal, 153-174.

EVP and Chief Sustainability and Innovation Officer

Ms. Monika Shrivastava, Head - Sustainability

Aishwarya Rai, Deputy Manager - Sustainability

JSW Cement