The European Commission recently announced the establishment of a ‘right to repair’. The right is being considered with a view of saving costs for consumers and facilitating the development of a circular economy. It includes repair during the legal guarantee, the right to repair after the legal guarantee has expired, and the right for consumers to repair products themselves.

Currently, EU contract laws give consumers the right to have faulty products repaired during the legal guarantee. Once the guarantee expires, repair may or may not be available for the products. This has largely resulted in discarding the products once they get any fault, small or big.

The Commission is now planning a number of initiatives to improve the reparability of products, including legislation on the right to repair, on empowering consumers for the green transition, a sustainable products initiative, design requirements for electronics, and measures making the broader economic context more favourable to repair.

European Environment Agency (EEA) in its 2020 report on electronics and obsolescence in a circular economy talks about absolute obsolescence (happens when a product no longer functions for objective reasons, because of a mechanical failure (mechanical obsolescence) or incompatibility of software (incompatibility obsolescence). The report also talks about Relative obsolescence, means that the product is still functional, but is considered obsolete because of a desire for a new item (psychological, style, cosmetic or aesthetic obsolescence); a new product has better quality, functionality or effectiveness (technological obsolescence); or the price of repair or upgrade is too high compared with a new product (economic obsolescence).

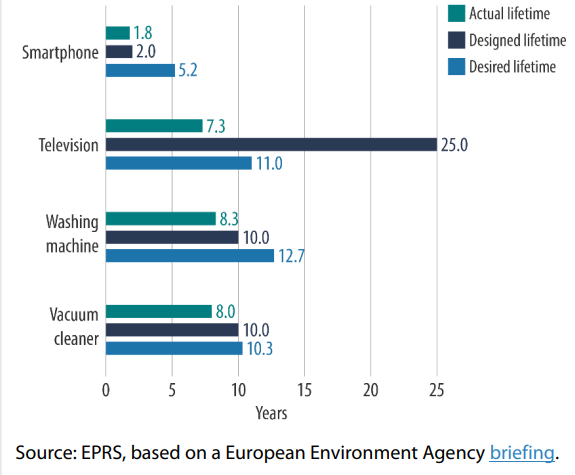

For some products, e.g. washing machines, the main driver for purchases of new items is absolute obsolescence. For mobile phones or TVs, relative obsolescence is more important. According to the EEA, a product becomes prematurely obsolescent when it breaks down early compared with what is possible (designed lifetime) or compared with what is desirable (desired lifetime).

The use of products in EU is usually lesser than the designed lifetime. Comparing this with Indian scenario, where repairability is ingrained in daily lives, the actual lifetime is far closer to the designed lifetime. This is because of a huge informal repair sector. This informal sector plays an extremely important role in increasing the lifetime of products in India. While we commend the informal sector, we also need to understand several factors that lead to making this huge market a success in India for several decades:

Cost effective repairs: The first and foremost point that makes repairability a success in India, is its affordability. Low cost of spare parts and cheap labour results in low cost of repairing.

For a customer, the cost of repair is far less than the new product. This becomes an important decision-making factor. Consumers are inclined towards repair rather than buying a new product. In EU, the cost of repair is higher, sometimes even more expensive than the cost of new product.

Accessibility: Proximity of repair services to the end-user, is another very important factor. If the solution is far and few, the consumer would find it difficult to access. In India, almost every locality has electrical, white goods, automobile and many more repair solutions. This is another factor that leads the consumer to access these solutions before ordering a new product.

Easy availability of tools: We as Indians have seen machinery and tool stores in every city and village. These machinery stores are one-stop solution for any kind of tool that may be required for repairing the machines at home. Repairing tools and their cheap cost have led the consumer to access them, sometimes even easier than access to new products.

Employability to the service industry: The repair industry has provided employment to a large sector in India. A recent report in 2021, the electronics repair market in India can help generate over five million direct jobs, with a potential to generate revenues of $20 billion per annum. The report by MAIT, the apex body representing the ICT and electronics manufacturing sector in India, the repair and calibration of electronic subassemblies and products is a $100 billion industry worldwide.

Training institutes and Knowledge transfer: Industrial training institutes (ITIs) provide formal education with the objective of ensuring a steady flow of skilled workers and reducing unemployment among the educated youth by training & equipping for suitable industrial employment as well as for self-employment. These have helped India generate a huge task force that could manage the repair sector.

Reducing waste creation: The repair of in-service electronic equipment enhances its life thereby reducing the amount of e-waste which would have been generated had the electronic gadget been discarded as waste.

Consumer behavior: By virtue of being a price-conscious market, India has seen a habit of repair developing over decades. By now, it has been ingrained in our habits. This behavior is an important factor that promotes repair in the country. Though, with the increase in per capita income and relative obsolescence, we can see a behavioral change that promotes consumption. But the Silverline can be drawn by the fact that this change is visible only in the metro cities.

According to a report launched at Electronics and Telecom Manufacturing Summit 2021 (MAIT-ETMS), titled ‘Electronic Hardware Repair Services Outsourcing’ (ERSO), high costs of repairing electronic goods in developed countries like the US and Europe are compelling the corporates to send goods overseas, where such repair services are provided at lower prices due to both skills and cost arbitrage.

Though “Right to Repair” is a welcome move by the EU, it will be difficult to deliver, unless other provisions are made by the member states. The right that considers saving costs for consumers and facilitating the development of a circular economy, needs a holistic implementation. India can be seen as a successful role model and can be followed by the member states to further the transition towards a Circular Economy.

Written by Shalini Goyal Bhalla