Introduction and background

Environmental degradation is a global problem. India also is facing the impact in many spheres, not only from the perspective of global warming and climate change, but also in the area of environment, ecology, and flora and fauna, resulting in the extinction of many living species.

As a conscious effort during the past decade, the author has initiated actions and taken steps to identify major industrial bulk wastes and their impact on the ecology and environment. Conservation of natural resources has been in the forefront.

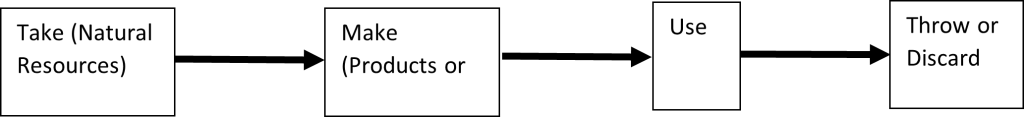

Linear Economy

The conventional way of the industry and trade has been “Take, Make, Use and Throw or Discard” depicted by the chart below.

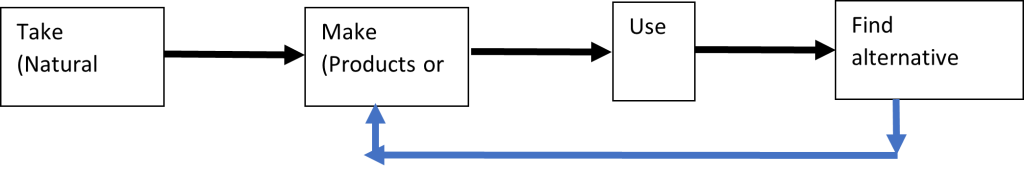

The Circular Economy:

As against the linear economy, we need to establish a circular economy, which can ensure a closed loop, as depicted below.

In the above, nothing is considered a waste. Instead, we find alternative uses for materials that are otherwise dumped as waste. In other words, these wastes become input for some other product or service

One of the many routes of addressing the circular economy is recycling various kinds of industrial wastes. The stress is on using different kinds of industrial wastes as a raw material or inputs to create a new application of the same and develop products and services for common use.

The concept and process of recycling waste should be looked from the angle of ecological balance of mother nature. The four types of living species have been the guiding factor in all our efforts. They are:

- The Herbivores who depend on plants and vegetation,

- The Carnivores who depend upon other living animals as their feed,

- The Saprophagous organism that obtain nutrient by consuming decomposing dead plants or animals’ biomass, and

- The Coprophagous animals that feed primarily or partially upon feces and excretion of other animals.

Our approach should be to draw a simile between the behavior of Saprophagous group (e.g. vultures, dogs, hyaenas, etc.) and Coprophagous group (e.g. dung beetles, house flies, some family of rabbits, capibaras, etc.) with an entirely new set of industries, which either have a philosophy of zero discharge or those which can use the waste of one or more industries as their inputs and produce a techno-commercially viable range of products and/or services.

To develop such a set of new industrial establishments, it is first necessary to understand the nature of the existing wastes and then find applications of the nature of such wastes to produce newer products or services.

Issues and problem areas

Over the decades, though we have been talking about recycling wastes, the main problem is the thinly distributed pattern of such wastes across the geography. Collection, segregation, integration and transportation to a central place for mass usage have been the major factors hindering the process of recycling. Most of the conventional wastes are very thinly distributed across the geography, just for example the likes of PET bottles, flexible wrappings and packing material, all kinds of products packaging, etc..

The differentiator: The SDGs

The Sustainable Development Goals (SDGs), also known as the Global Goals, were adopted by the United Nations in 2015 as a universal call to action to end poverty, protect the planet, and ensure that by 2030, for all people to enjoy peace and prosperity.

The 17 SDGs are integrated—they recognize that action in one area will affect outcomes in others, and that development must balance Social, Economic and Environmental sustainability.

While all the 17 SDGs have been kept in mind, however, in our efforts towards ensuring circular economy, it is felt that the following SDGs may be given priority in our work area in sustainability., viz:

- GOAL 3: Good Health and Well-being

- GOAL 4: Quality Education

- GOAL 6: Clean Water and Sanitation

- GOAL 7: Affordable and Clean Energy

- GOAL 8: Decent Work and Economic Growth

- GOAL 9: Industry, Innovation and Infrastructure

- GOAL 12: Responsible Consumption and Production

- GOAL 17: Partnerships to achieve the Goal

Waste Recycling has come to stay and is accepted as a viable proposition. However, the issues with waste recycling are its thinly distributed characteristic, spread over a wide geographic area. The collection, assimilation, aggregation, segregation etc. are observed to be the main constraints. These parameters, in turn, effect the technoeconomic or techno commercial viability or feasibility of the projects. Many efforts are being made by various interested agencies and individuals across the world, however, for those starting to make a dent, it is advised that they can start concentrating on the low hanging fruits with potential for high yields, i.e., those bulk industrial wastes which are captively available in a given location. The idea behind this approach is that though we call them low hanging, they are indeed the fruits which can replace many of the natural resources, which is one of the major SDGs.

The “S” in the SDGs should be the driving force in all our efforts, as it aims at Environmental Sustainability. However, unfortunately enough, the Economic / Commercial is considered more important. Hence, it is prudent to initially identify those of the bulk wastes which have a promising economic/commercial viability, it in turn will serve the ends of the environmental sustainability too. The commercial sustainability is what drives people to do something and make money.

If we want a successful circular economy project working, Techno-commercial viability is the name of the game.

Examples of a few of such areas or wastes are;

1. Cupola furnace slag[1]:

The Indian Metal casting (Foundry Industry) is well established. According to the recent World Census of Castings by Modern Castings, USA, India Ranks as 2nd largest casting producer producing estimated 7.44 Million MT of various grades of Castings as per International standards .

The various types of castings which are produced are ferrous, nonferrous, Aluminium Alloy, graded cast iron, ductile iron, Steel etc for application in Automobiles, Railways, Pumps Compressors & Valves, Diesel Engines, Cement/Electrical/Textile Machinery, Aero & Sanitary pipes & Fittings etc & Castings for special applications. However, Grey iron castings is the major share accounting for approximately 70 % of total castings produced.

There are approx. 4,500 units, out of which 80% can be classified as Small Scale units & 10% each as Medium & Large-Scale units. Approx 500 units are having International Quality Accreditation. The large foundries are modern & globally competitive & are working at nearly full capacity. Most foundries use cupolas using LAM Coke. There is growing awareness about environment & many foundries are switching over to induction furnaces & most of the units in Agra have changed over to coke less cupolas.

[1] https://foundryinfo-india.org/About_Us/profile_of_indian.aspx

All these units, as a part of the processing, generated large quantities of Slag. It is estimated that the iron foundries alone account for about 1 million tonnes of such slag generation.

While there are many possibilities for developing more useful products from such slag, one such demonstration projects was undertaken by the Foundation for SMEs, in Samalkha town of Haryana State. The small demonstration project of 2011 lead them to get an EU grant through the ministry of science and technology, GOI, and 50 such slag recycling units have been established in major iron foundry clusters, spread over from Coimbatore in south to Jalandhar in north.

2. Marble dust of Rajasthan[2]:

India is one of the biggest marble producing country in the world (∼10%). State of Rajasthan has nearly 85% of marble production capacity. The massive quantity of marble waste fine particulates generated in marble industry has become a major environmental hazard issue. A circular economy approach is to look at this dust as a resource and not as a waste and a problematic item. A more detailed and in depth look in to this material is to know that it contains various minerals such as calcite (CaCO3) and dolomite (CaMg (CO3)2). The particle sizes of marble waste particulates is about 200 μm (D90). The chemical composition of marble wastes reveals oxides of calcium (CaO), silica (SiO2), alumina (Al2O3) and alkaline oxides (Na2O, K2O). Apart from that, iron oxide, mica, fluorine, chlorite and organic matter have also been noticed. We should understand that although a dust, it is still marble. All our technical knowledge needs to be aimed at either using it in as it is form or convert this dust in to solid blocks. Some of the processes like sintering etc. will be useful to address the issue. During the period 2012-14, the author was able to develop flooring and wall tiles and building blocks from such dust. Of late, there are many industrial units, particularly in Rajasthan and Gujrat states, which are developing commercially viable products from this material. Through such efforts, we will be able to save the quarrying of virgin raw materials from mother earth to the extent of about 5-6 million metric tons annually. (Ref. CPCB-Zonal office- Bhopal)

3. Rice Husk Ash:

India produces about 110 Million tonnes of paddy annually. A typical rice mills produces about 22% by weight of paddy as Rice Husk, which upon burning as fuel, generates about 25% by weight of the husk as Rice Husk Ash. This amounts to about an estimated 5.5 million tons of waste annually. Just as said previously, if we stop treating this ash as a waste and look at it as a resource, it turns out to be a rich source of Amorphous Reactive Silica, containing about 85 to 98% of the entire mass. Amorphous silica is a rich and very useful raw material, with scope for many high value-added applications, right up to manufacturing of the Silicon Chips.\

[2] https://www.sciencedirect.com/science/article/abs/pii/S2452223618300257

4. Vegetable market yard waste[3]: It is a very common sight to see tonnes of waste vegetables being discarded and dumped in vegetable market yards. Apart from looking dirty, these wastes are a major source of generation of various hazardous bacterial matter, which is not only a health hazard but also has unacceptable breathing effects and smell. Treating or processing them on the same day, within hours of their generation may be used as a rich source of cattle feed or use for biogas generation. Composting, Vermicomposting are a few other options.

5. Flowers offered in thousands of temples daily[4]:

Because of our inherent way of worshipping Gods, it is estimated that Every day a few million people go to temples, mosques, gurudwaras and other places of worshipping. Also, traditionally, Indians also use flowers during the rituals of the dead. A major portion of these flowers finally end up in various water bodies, with their implied problems. It is estimated that 800 million tonnes of flowers are offered across the temples, mosques and gurudwaras etc. in the country. More than 8 million tonnes of flowers are dumped in the river every year, along with toxic pesticides and insecticides used to grow them. In India many places of worship generate20 tonnes of flower waste daily. Understanding the fact that these flowers have a very small and limited life, it is advised that the used flowers be collected within hours of their disposal. Simple processes like Fractional Distillation may offer huge potential for producing fragrant materials and high value aromatic composites from them. Similarly, a variety of plant leaves like Tulsi etc, are also used for various religious processes. These are potential sources of established medicinal values.

6. Sludge from various industries e.g., bulk drugs, sugar plants, paper plants, fertilizer

7. Sludge from various industries e.g., bulk drugs, sugar plants, paper plants, fertilizer plants so on and so forth

8. Waste plastics: These are all the products, possible and made from different types of waste plastics.

9. Tailings from Bauxite, Iron ore, Copper, Zinc and other metal ores mines etc.

[4] https://www.researchgate.net/publication/305317610_VEGETABLE_WASTE_RECYCLING

[5] Rohit Kumar Sharma International agribusiness management institute, Anand Agricultural university anand, Gujarat.

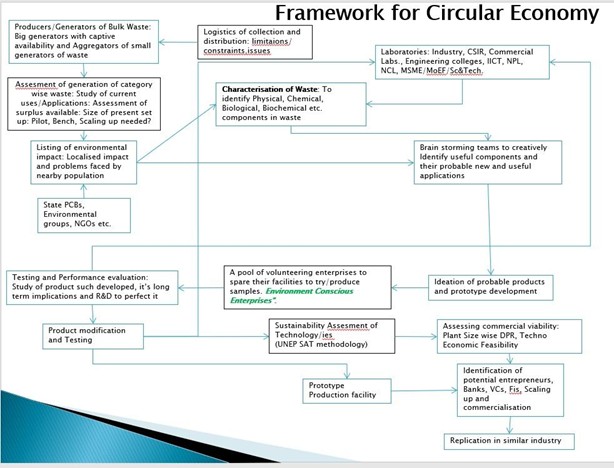

The Circular Economy Framework

While attempting to develop such useful applications from bulk wastes, in the entire cycle of “concept to viable implementation”, one would face some situations and road blocks to effective and fast implementation of the projects.

Development of prototype products needs some basic resources and access to workshops, machinery and laboratories. An individual does not have easy access to such needs. Access to good industry having the needed infrastructure, viz: laboratories for waste sample analysis and its characterization, prototype development, product testing, preparation of Techno Financial feasibility (Detailed Project Report), Market Research, market segment identification, costing, packaging and pricing of the product, etc. Almost all these stages in the life cycle are costly affairs and need large finances, which any startup company or an entrepreneur can ill afford, and thus, most of the ideas never see light of the day and die down their own natural death.

Based on our experience in this area, it is recommended that a framework as depicted below needs to be put in place. Under this, the most important action is to create a policy to forcefully involve all the national and public resources like the CSIR laboratories, National Physical Lab, National Chemical Lab, All IITs and NITs, IIMs, State level ITIs, Engineering colleges and Engineering diploma institutes, common facility centers supported by any governmental agency and many other similar establishments. They should be asked to provide their services to anyone who is working in the circular economy domain and needs their resources. As the entire effort is in the national interest, these entities may be made to offer about at least 5% of their resources to anyone who shows interest and needs technical advice, expertise and resources under their control.

Ex Chairperson Center for Innovation and Entrepreneurship Development (CIED)

Birla Institute of Management Tecchnology