Edible food loss throughout the supply chain presents a major challenge to sustainable agricultural development. Globally, around 14 percent of food is lost during post-harvest handling, logistics, and transportation, excluding retail (FAO, 2019). The food waste from retailers amounts to approximately 1.05 billion tonnes annually. This averages 132 kilograms per person per year (UNEP, 2024). This issue is more concerning in developing and South Asian nations like India, where rapid urbanization and evolving consumption patterns exacerbate food supply chain inefficiencies.

China generates some of the highest food waste levels, ranging from 101 to 150 kg per capita annually (Zhang et al., 2020; Lo & Woon, 2016). Bangladeshi cities, including Chittagong and Khulna, report figures between 57 and 117 kg (Sujauddin, Huda, and Hoque, 2008; UN-Habitat, 2021). India also exhibits wide variations, with Uttarakhand recording food waste levels between 20 and 73 kg (Suthar & Singh, 2015; Grover & Singh, 2014; Rawat & Daverey, 2018), while Karnataka reports 83 kg per capita (UN-Habitat-unpublished).

Although India has a relatively lower per capita food waste, it ranks among the highest in total household food waste, generating 78.19 million tonnes annually. It follows China, which leads with 108.67 million tonnes, while Pakistan and Bangladesh record 30.75 million tonnes and 14.10 million tonnes, respectively (UNEP, 2024). This significant volume of loss worsens global food insecurity and contributes to environmental degradation through unnecessary greenhouse gas (GHG) emissions, water consumption, and land-use inefficiencies (Magry & Narula, 2021).

For several decades, concerted efforts have been made to mitigate food loss, recognizing its significant economic, environmental, and social implications. There are many fundamental approaches, for instance, ‘prevention’ and ‘reduction’, which were proposed by Magalhaes et al. (2022) and Moraes et al. (2021). The prevention strategy focuses on proactive measures implemented before production begins, whereas reduction comes into play after production. Other than these approaches, the circular economy (CE) concept closely aligns with the principles of minimization of food loss (Kusumowardani et al., 2022). The CE principles extend beyond waste management to emphasize resource efficiency and cross-sectoral integration (Sarkar et al., 2022). The CE approach offers a viable solution to address the food loss challenges by promoting sustainable resource use and waste minimization (Chiaraluce et al., 2021; Jurgilevich et al., 2016; Velasco-Munoz et al., 2022). It is grounded in the principles of reduce, reuse, and recycle, with some scholars expanding the framework to include additional strategies such as redesign, repair, and remanufacturing (Bloise, 2020; Perdana et al., 2023).

Also, integrating food waste valorization within the CE model reduces food losses, optimizes resource use, and minimizes environmental degradation (Lin et al., 2013). Valorization strategies contribute to a more sustainable and efficient food system, such as conversion into renewable energy sources such as biogas, hydrogen, and bioethanol. Technologies like anaerobic digestion and thermal gasification break down organic food waste into biofuels, which are further used for energy generation or as an alternative to fossil fuels (Zhang et al., 2014)

The Akshaya Patra Foundation, a prominent non-profit organization in India, operates centralized kitchens across various states to provide mid-day meals to schoolchildren. To manage the organic waste generated from these operations, the foundation has established biogas plants in several kitchens. These plants process approximately 350 kilograms of organic waste daily, converting it into biogas through anaerobic digestion. The biogas produced is utilized in the kitchens’ cooking processes, resulting in a monthly savings of around INR 38,500 on energy expenses. This initiative not only reduces the volume of waste directed to landfills but also exemplifies an effective waste-to-energy conversion, embodying the circular economy’s emphasis on resource efficiency and sustainability

Further, anaerobic digestion is widely used in developed countries where food waste is processed in large-scale biogas plants. In these facilities, microbial action breaks down organic matter in oxygen-deprived conditions, producing methane-rich biogas (Thi et al., 2016). Similarly, thermal gasification, a high-temperature process, converts food waste into hydrogen and syngas (Muangrat, 2013). Large-scale bioenergy projects utilize discarded agricultural waste to produce bioethanol and biodiesel, including fruit peels, vegetable residues, and expired food. These projects reduce the volume of food waste and contribute to the energy sector’s decarbonization (Ong et al., 2018).

PepsiCo’s Frito-Lay unit in Pune generates around 18 metric tonnes of waste daily, including potato peels and process waste. To address this, they implemented a biogas methane plant that converts organic waste into biogas. This biogas is then used to fuel their ‘Kurkure’ chips production line, replacing traditional LPG usage. The initiative has led to a 65% reduction in waste and an annual decrease of 390 tonnes in greenhouse gas emissions.

Source: https://cleanindiajournal.com/tag/successful-biogas-plant/amp/

Repurposing as animal feed and organic fertilizers is another effective strategy for food waste valorization. The transformation of surplus food into livestock feed has been successfully implemented in various countries, where agricultural waste such as rice husks, wheat bran, and oilseed cakes are processed into nutritious feed supplements for cattle, poultry, and fish (Lin et al., 2013). This approach reduces dependence on conventional animal feed, which often requires large amounts of water and land resources, and lowers feed costs for farmers, making it a financially viable solution (Nath et al., 2023).

Source: https://avpn.asia/resources/case-study/transforming-food-surplus-and-wastage-to-animal-feeds/

Krimanshi Technologies is an award-winning social enterprise that manufactures high-quality animal feeds from surplus agriculture and food residues. They collect food waste from agricultural hubs, such as fruit leaves, crushed fruits, and vegetable waste, and process them into various types of feeds. This approach provides affordable, nutritious feed solutions for cattle, benefiting small dairy farmers year-round without compromising quality. By upcycling waste into animal feed, Krimanshi reduces greenhouse gas emissions and generates livelihoods for low-income dairy farmers. Their products have led to up to a 20% increase in milk production among farmers, along with a 10% reduction in feed costs and a 60% decrease in veterinary expenses.

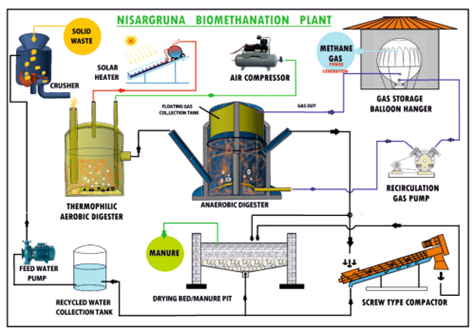

The Nisargruna biogas plant offers “Zero garbage – Zero effluent” and processes various biodegradable wastes, including kitchen waste, through a combination of aerobic and anaerobic digestion. The process yields biogas with a methane content of 70–80%, suitable for cooking or heating. Additionally, it produces a weed-free organic manure slurry with a carbon-to-nitrogen ratio of 12:1 to 16:1, serving as an effective soil conditioner. This technology reduces reliance on synthetic fertilizers and supports circular food production systems.

Biofertilizers from food waste are a sustainable alternative to chemical fertilizers as they contribute to regenerative agriculture and circular food production systems (Magry & Narula, 2021). For example, fruit and vegetable scraps are composted or treated with microbes to create nutrient-rich organic fertilizers. These biofertilizers improve soil health and boost crop yields.

Source: https://www.barc.gov.in/technologies/kitchen/index.html

Waste Recycling has come to stay and is accepted as a viable proposition. However, the issues with waste recycling are its thinly distributed characteristic, spread over a wide geographic area. The collection, assimilation, aggregation, segregation etc. are observed to be the main constraints. These parameters, in turn, effect the technoeconomic or techno commercial viability or feasibility of the projects. Many efforts are being made by various interested agencies and individuals across the world, however, for those starting to make a dent, it is advised that they can start concentrating on the low hanging fruits with potential for high yields, i.e., those bulk industrial wastes which are captively available in a given location. The idea behind this approach is that though we call them low hanging, they are indeed the fruits which can replace many of the natural resources, which is one of the major SDGs.

The “S” in the SDGs should be the driving force in all our efforts, as it aims at Environmental Sustainability. However, unfortunately enough, the Economic / Commercial is considered more important. Hence, it is prudent to initially identify those of the bulk wastes which have a promising economic/commercial viability, it in turn will serve the ends of the environmental sustainability too. The commercial sustainability is what drives people to do something and make money.

If we want a successful circular economy project working, Techno-commercial viability is the name of the game.

Food waste valorization is also trending in the pharmaceutical and cosmetic industries. Many bioactive compounds, such as antioxidants, polyphenols, and essential oils, can be extracted from discarded food materials and repurposed commercially (Yadav et al., 2024). Fruit and vegetable peels, which are typically discarded, are rich in vitamins, flavonoids, and anti-ageing compounds, which are now extracted and used in skincare and personal care products (Mirabella et al., 2014). The pharmaceutical industry also applies food waste-derived compounds in drug formulations (Papargyropoulou et al., 2014).

Waste Management Policy in India

The government of India has implemented several key programs to support a circular food economy and collective waste management. The National Food Security Mission (NFSM) and the Public Distribution System (PDS) ensure that surplus food is redistributed to vulnerable populations, minimizing wastage. The Pradhan Mantri Kisan SAMPADA Yojana (PMKSY) supports food processing and preservation, extending shelf life and reducing post-harvest losses. Urban food waste management is strengthened through the Swachh Bharat Mission, promoting composting and organic waste recycling to convert waste into valuable resources like biofertilizers. Sustainable farming practices encouraged under the National Mission on Sustainable Agriculture (NMSA) and Pradhan Mantri Krishi Sinchai Yojana (PMKSY) reduce food losses at the production stage, ensuring optimal use of resources. Investments in cold chain infrastructure under Operation Greens ensure efficient storage and transport of perishables crops like tomato, onion, potato, reducing spoilage and integrating food systems into a closed-loop economy.

Although there is much policy push to convert food waste to other value-added products, the stakeholders in the system need to make collective efforts to overcome challenges. Waste collection and segregation are significant challenges, and companies need to come forward to educate workers, farmers, and other stakeholders. Consumer education plays an important role, and there must be efforts to inform them how they can minimize waste. Efforts are being made at a large scale, yet we believe that small-scale household models or community models may bring a significant change across the country. We need to experiment with such community models and popularise them. These are a revenue source for many households. Given the gaps in global food and nutritional security, such as food inflation and decreasing food productivity, these circular business models may play an important role not only in tacking with food supply chain crises but also in the overall sustainability of the system through the reduction of GHG emissions and social empowerment.

References:

- Bloise, C., 2020. Collaboration in a circular economy: learning from the farmers to reduce food waste. Journal of Enterprise Information Management 33 (4): 769–789

- Chiaraluce, G., Bentivoglio, D., Finco, A., 2021. Circular economy for a sustainable agrifood supply chain: a review for current trends and future pathways. Sustainability 13 (16): 9294

- 2019. The State of Food and Agriculture. Moving forward on food loss and waste reduction. Rome.

- Grover, P. and Singh, P. 2014. An analytical study of effect of family income and size on per capita household solid waste generation in developing countries. Review of Arts and Humanities 3(1), 127-143

- Jurgilevich, A., Birge, T., Kentala-Lehtonen, J., Korhonen-Kurki, K., Pietikäinen. J., Saikku, L. and Schösler, H. 2016. Transition towards Circular Economy in the Food System. Sustainability, 8 (1), 69

- Kusumowardani, N., Tjahjono, B., Lazell, J., Bek, D., Theodorakopoulos, N., Andrikopoulos P., and Priadi, C. R. 2022. A circular capability framework to address food waste and losses in the agri-food supply chain: the antecedents, principles and outcomes of circular economy. Journal of Business Research, 142, 17-31

- Lin, C. S. K., Pfaltzgraff, L. A., Herrero-Davila, L., Mubofu, E. B., Abderrahim, S., Clark, J. H., and Thankappan, S. 2013. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy & Environmental Science, 6 (2): 426-464

- Lo, I. M. C., and Woon, K. S. 2016. Food waste collection and recycling for value-added products: potential applications and challenges in Hong Kong. Environmental Science and Pollution Research 23 (8): 7081-7091

- Magalhaes, V. S. M., Ferreira, L. M. D. F., and Silva, C. 2022. Prioritising food loss and waste mitigation strategies in the fruit and vegetable supply chain: a multi-criteria approach. Sustainable Production and Consumption 31, 569–581

- Magry, M. A. and Narula, S. A. 2021. Sustainability of agri-food supply chains through innovative waste management models. Valorization of Agri-Food Wastes and By-Products. Elsevier. 591–605

- Mirabella, N., Castellani, V., and Sala, S. 2014. Current options for the valorization of food manufacturing waste: A review. Journal of Cleaner Production 65: 28-41

- Moraes, N. V., Lermen, F. H., and Echeveste, M. E. S. 2021. A systematic literature review on food waste/loss prevention and minimization methods. Journal of Environmental Management 286, 112268

- Muangrat, R. 2013. A review: Utilization of food wastes for hydrogen production under hydrothermal gasification. Environmental Technology Reviews, 2 (1): 85-100

- Nath, P. C., Ojha, A., Debnath, S., Sharma, M., Nayak, P. K., Sridhar, K., and Inbaraj, B. S. 2023. Valorization of Food Waste as Animal Feed: A Step towards Sustainable Food Waste Management and Circular Bioeconomy. Animal (Basel) 13 (8): 1366

- Ong, K. L., Kaur, G., Pensupa, N., Uisan, K., and Lin, C. S. K. 2018. Trends in food waste valorization for the production of chemicals, materials and fuels: Case study South and Southeast Asia. Bioresource Technology, 248: 100-112

- Papargyropoulou, E., Lozano, R., Steinberger, J. K., Wright, N., and bin Ujang, Z. 2014. The food waste hierarchy as a framework for the management of food surplus and food waste. Journal of Cleaner Production, 76: 106-115

- Perdana, T., Kusnandar, K., Perdana, H. H., and Hermiatin, F. R. 2023. Circular supply chain governance for sustainable fresh agricultural products: Minimizing food loss and utilizing agricultural waste. Sustainable Production and Consumption 41: 391-403

- Rawat, S. and Daverey, A. 2018. Characterization of household solid waste and current status of municipal waste management in Rishikesh, Uttarakhand. Environmental Engineering Research 23(3), 323-329.

- Sarkar, B., Debnath, A., Chiu, A.S.F., and Ahmed, W. 2022. Circular economy-driven two-stage supply chain management for nullifying waste. Journal of Cleaner Production 339, 130513

- Sujauddin, M., Huda, S.M.S. and Hoque, A.T.M.R. 2008. Household solid waste characteristics and management in Chittagong, Bangladesh. Waste Management 28(9), 1688-1695.

- Suthar, S. and Singh, P. 2015. Household solid waste generation and composition in different family size and socio-economic groups: A case study. Sustainable Cities and Society 14, 56-63.

- Thi, N. B. D., Lin, C. Y., and Kumar, G. 2016. Waste-to-wealth for valorization of food waste to hydrogen and methane towards creating a sustainable ideal source of bioenergy. Journal of Cleaner Production, 122, 29-41

- 2024. Food Waste Index Report. Think Eat Save Tracking Progress to halve global food waste.

- UN-Habitat. 2021. Waste Wise Cities Tool in Khulna, Bangladesh.

- UN-Habitat (unpublished). Waste Wise Cities Tool, unpublished data

- Velasco-Munoz, J. F., Aznar-Sanchez, J. A., Lopez-Felices, B., and Roman-Sanchez, I. M., 2022. Circular economy in agriculture. An analysis of the state of research based on the life cycle. Sustainable Production and Consumption 34, 257–270

- Yadav, S., Malik, K., Moore, J. M., Kamboj, B. R., Malik, S., Malik, V. K., Arya, S., Singh, K., Mahanta, S., and Bishnoi, D. K. 2024. Valorisation of Agri-Food Waste for Bioactive Compounds: Recent Trends and Future Sustainable Challenges. Molecules 29 (9): 2055

- Zhang, C., Su, H., Baeyens, J., and Tan, T. 2014. Reviewing the anaerobic digestion of food waste for biogas production. Renewable and Sustainable Energy Reviews, 38: 383-392

- Zhang, H., Liu, G., Xue, L., Zuo, J., Chen, T., Vuppaladadiyam, A., and Duan, H. 2020. Anaerobic digestion-based waste-to-energy technologies can halve the climate impact of China’s fast-growing food waste by 2040. Journal of Cleaner Production 277: 123490

Director-CCS, National Institute of Agricultural Marketing,

Ministry of Agriculture and Farmers Welfare, GoI

Research Officer CCS National Institute of Agricultural Marketing

Ministry of Agriculture and Farmers Welfare, GoI